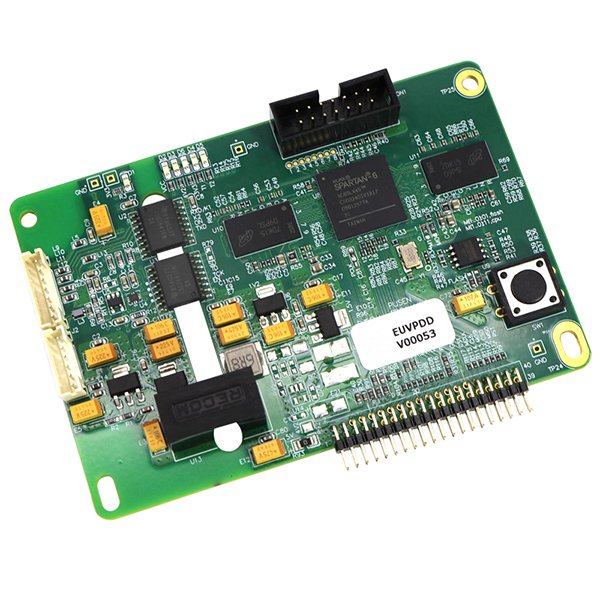

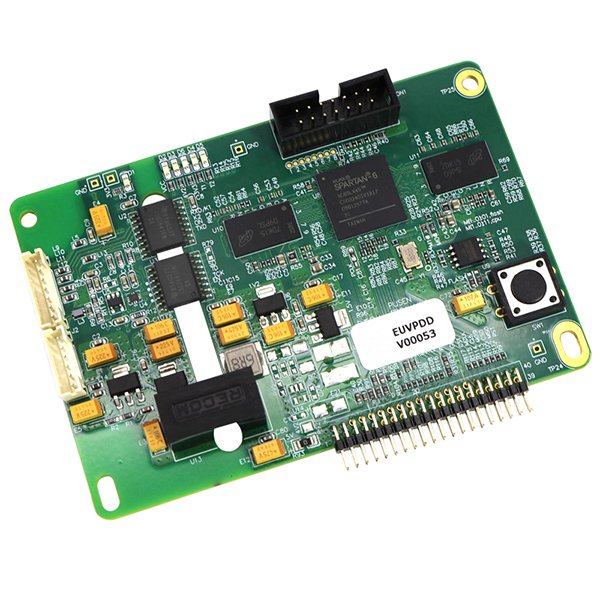

Uvavanyo lomgangatho / uvavanyo

Ukuvavanywa kwe-PCB kuqhutywa iimvavanyo ezahlukeneyo zebhodi eziprintiweyo ukuqinisekisa umgangatho wabo kunye nokusebenza kwabo, ukuqinisekisa ukususwa ngokuchanekileyo nasiphi na isiphene okanye imiba enokuthi ifumaneke ngokulandelelana kunye nokucutha iindleko. Ixabiso lokugqibela.

Singabonelela ngeenkonzo ezahlukeneyo zokuvavanywa kwe-PCB, kubandakanya:

Incwadi yokuhlola / yokuhlola:Siye safumana abahloli be-PCB abathingelayo uhlolo olubonakalayo lwezamasano kwimvavanyo ezininzi ukuqinisekisa uhlolo olufanelekileyo lwee-PCB kunye nezinto zabo, ukuqinisekisa umgangatho wemveliso.

Incwadi yokuhlola / yokuhlola:Siye safumana abahloli be-PCB abathingelayo uhlolo olubonakalayo lwezamasano kwimvavanyo ezininzi ukuqinisekisa uhlolo olufanelekileyo lwee-PCB kunye nezinto zabo, ukuqinisekisa umgangatho wemveliso.

I-Microscopic Slice Slice SliceUvavanyo lwe-slice lwe-PCB lubandakanya ukusika iBhodi yeSekethe kumacandelo amancinci okujonga kunye nohlalutyo, ukuze kuchongwe iingxaki ezinokubakho kunye neziphene.

I-Microscopic Slice Slice SliceUvavanyo lwe-slice lwe-PCB lubandakanya ukusika iBhodi yeSekethe kumacandelo amancinci okujonga kunye nohlalutyo, ukuze kuchongwe iingxaki ezinokubakho kunye neziphene.

Uvavanyo lwe-slice luhlala lwenziwa kumanqanaba okuqala lwemveliso yebhodi yebhokisi yebhodi yesiphaluka ukuqinisekisa ukuhlolwa kunye nokulungiswa kwemicimbi ngexesha loyilo kunye nenkqubo yokwenza. Le ndlela inokujonga i-welding, unxibelelwano lwe-interlather, ukuchaneka kombane, kunye neminye imiba. Xa uqhuba iimviwo ze-biopsy, i-microscope okanye i-microscope ye-elektroni idla ngokusetyenziswa ukugcina nokuhlalutya izilayi.

Uvavanyo lombane wePCB:Uvavanyo lombane lwe-PCB lunokunceda ekuqinisekiseni ukuba ngaba iiparamitha zombane kunye nokusebenza kweBhodi yeSekethe zidibana nokulindelwa, kwaye kunokuchonga iziphene kunye neengxaki.

Uvavanyo lombane wePCB:Uvavanyo lombane lwe-PCB lunokunceda ekuqinisekiseni ukuba ngaba iiparamitha zombane kunye nokusebenza kweBhodi yeSekethe zidibana nokulindelwa, kwaye kunokuchonga iziphene kunye neengxaki.

Uvavanyo lombane lwe-PCB luhlala lubandakanya uvavanyo lonxibelelwano, uvavanyo lokunyangeka, uvavanyo lokuvavanywa, ukuvavanywa, ukuvavanywa kwengqibelelo, kunye nokuvavanywa kokusetyenziswa komqondiso.

Uvavanyo lombane lwePCB lunokusebenzisa izixhobo ezahlukeneyo zovavanyo kunye neendlela, ezinjengeendawo zovavanyo lwedijithali, i-oscilloskos, iziphumo zoVavanyo ziya kurekhodwa kwiNgxelo yovavanyo.

Uvavanyo lwe-AOI:Uvavanyo lwe-AOI (uhlolo lwendawo oluzenzekelayo) yindlela yokufumana iibhodi zesekethe eziprintiweyo ngeendlela zamehlo. Ingasetyenziselwa ukuqaphela ngokukhawuleza inkqubo kunye neengxaki kwinkqubo yemveliso eprintiweyo, kuphephe iimpazamo kwimveliso yemveliso, kwaye uphucule umgangatho weebhodi zesekethe eziprintiweyo. Umgangatho onokuthenjwa, ukunciphisa amazinga okusilela, kunye nokuphucula ubuchule bokwenza impumelelo kunye nesivuno semveliso.

Uvavanyo lwe-AOI:Uvavanyo lwe-AOI (uhlolo lwendawo oluzenzekelayo) yindlela yokufumana iibhodi zesekethe eziprintiweyo ngeendlela zamehlo. Ingasetyenziselwa ukuqaphela ngokukhawuleza inkqubo kunye neengxaki kwinkqubo yemveliso eprintiweyo, kuphephe iimpazamo kwimveliso yemveliso, kwaye uphucule umgangatho weebhodi zesekethe eziprintiweyo. Umgangatho onokuthenjwa, ukunciphisa amazinga okusilela, kunye nokuphucula ubuchule bokwenza impumelelo kunye nesivuno semveliso.

Kuvavanyo lwe-AOI, izixhobo ezibonakalayo ezichongiweyo ezifana neekhamera eziphezulu, imithombo yokukhanya, kunye nesoftware yokulungisa umfanekiso zisetyenziselwa ukuskena i-PCB edwelisiweyo, kwaye ke imifanekiso efunyenweyo ithelekiswa netemplate eseleyo. Ewe, ukufumanisa ngokuzenzekelayo isiphene kunye nemiba, kubandakanya ukudibanisa impahla, izinto, imijikelezo emifutshane kunye nesekethe ezivulekileyo, ukuchaneka, umphezulu,

I-ICT:Kuvavanyo lwesekethe kusetyenziswa ukuvavanya izinto ze-elektroniki kunye nesekethe yokusebenza kwiBhodi yeSekethe. Uvavanyo lwe-ICT lunokuqhutywa kumanqanaba ahlukeneyo emveliso, njengokwenziwe emva kwemveliso ye-PCB, ngaphambi okanye emva kokufakwa kwecandelo, ukuchonga iingxaki kwiBhodi yeSekethe kwaye ichaphazele ngendlela yexesha lesekethe.

I-ICT:Kuvavanyo lwesekethe kusetyenziswa ukuvavanya izinto ze-elektroniki kunye nesekethe yokusebenza kwiBhodi yeSekethe. Uvavanyo lwe-ICT lunokuqhutywa kumanqanaba ahlukeneyo emveliso, njengokwenziwe emva kwemveliso ye-PCB, ngaphambi okanye emva kokufakwa kwecandelo, ukuchonga iingxaki kwiBhodi yeSekethe kwaye ichaphazele ngendlela yexesha lesekethe.

Ukuvavanywa kokuvavanywa kwe-ICT ngokusetyenziswa kwezixhobo ze-ICT kunye nesoftware yokuvavanya ngokwamacandelo e-elektroniki kunye nezihlanganisi kwii-PCB. Isixhobo sokuvavanya sinxibelelana namanqaku ovavanyo kwiBhodi yeSekethe ngokusebenzisa amathuba kunye ne-cladis ukufumana iimpawu zombane zecandelo le-elektroniki kwiBhodi yeSoftware kwiBhodi yeSiphalukana nayo Qinisekisa ukuba unxibelelwano lwayo lombane lusebenza njengoko lwenziwe.

Uvavanyo lwenaliti ezibhabha:Uvavanyo lwe-nenaliting ye-inaliti lusebenzisa inkqubo yeproPheli ezenzekelayo yokuvavanya uqhagamshelo lwesekethe kwi-PCB. Le ndlela yovavanyo ayifuni ukungqinisisa okubizayo kunye nexesha lokuphucula izinto, kodwa endaweni yoko lisebenzisa amathuba ashukumayo ukunxibelelana nomgangatho wePCB ukulungiselela uxhulumaniso lwesekethe kunye nezinye iiparameter.

Uvavanyo lwenaliti ezibhabha:Uvavanyo lwe-nenaliting ye-inaliti lusebenzisa inkqubo yeproPheli ezenzekelayo yokuvavanya uqhagamshelo lwesekethe kwi-PCB. Le ndlela yovavanyo ayifuni ukungqinisisa okubizayo kunye nexesha lokuphucula izinto, kodwa endaweni yoko lisebenzisa amathuba ashukumayo ukunxibelelana nomgangatho wePCB ukulungiselela uxhulumaniso lwesekethe kunye nezinye iiparameter.

Uvavanyo lwe-Inaliting Inaliti yindlela yokuvavanywa engaqhakalanga yovavanyo enokuvavanya nayiphi na indawo yeBhodi yeBhodi, kubandakanya neebhodi zesekepheni ezincinci nezingenayo. Izibonelelo zolo ndlela lovavanyo ziindleko zovavanyo eziphantsi, ixesha lovavanyo olufutshane, ngokulula kotshintsho loyilo lwesekethe, kunye novavanyo lwesampulu ekhawulezileyo.

Uvavanyo lwesekethe olusebenzayo:Ukuvavanywa kokuSebenza okusebenzayo yindlela yokuqhuba uvavanyo olusebenzayo kwi-PCB ukuqinisekisa ukuba uyilo luhlangabezana nawo kunye neemfuno. Yindlela yovavanyo ebanzi enokusetyenziselwa ukukhangela intsebenzo, umgangatho womqondiso, uNcisa lweSekethe, kunye neminye imisebenzi yee-PCB.

Uvavanyo lwesekethe olusebenzayo:Ukuvavanywa kokuSebenza okusebenzayo yindlela yokuqhuba uvavanyo olusebenzayo kwi-PCB ukuqinisekisa ukuba uyilo luhlangabezana nawo kunye neemfuno. Yindlela yovavanyo ebanzi enokusetyenziselwa ukukhangela intsebenzo, umgangatho womqondiso, uNcisa lweSekethe, kunye neminye imisebenzi yee-PCB.

Uvavanyo lwesekelo olusebenzayo luhlala luqhutywa emva kokuba i-PCB Wiring igqityiwe, kusetyenziswa iinkqubo zokuvavanya kunye neenkqubo zokuvavanya ukuthobela ezona meko zisebenzayo zePCB kwaye zivavanye impendulo yayo. Inkqubo yovavanyo inokuphunyezwa kwinkqubo yesoftware, enokuvavanya imisebenzi eyahlukeneyo ye-PCB, kubandakanya igalelo / iziphumo, ixesha lokuhambisa amandla, ezinye iiparamitha. Kwangelo xesha, eli phepha lingafumanisa imiba emininzi enokubakho nge-PCBS, ezinjengeesekethe ezifutshane, iisekethe ezivulekileyo, uqhagamshelo olungachanekanga, njl.

Uvavanyo lweSekelo oluDibeneyo yindlela yokuvavanya eyakhiweyo efuna ukuba inkqubo kunye noyilo lovavanyo lwe-PCB nganye. Ke ngoko, iindleko ziphezulu, kodwa inokubonelela ngeziphumo zovavanyo ezichanekileyo ngakumbi.